By Giulio Marolda Chelli, Recent graduate in Energy Engineering

On September 1, 2018 the FSA 12 group (Twelfth “Field Study Abroad”) met engineer Marco Ricci at the Crystal Palace in San Jose, Costa Rica, today known as Hotel Exe. In 2012, the hotel made the decision to use renewable energy as much as possible by contacting the CIRPS Research Group and the FSA conducted by Prof. Andrea Micangeli to design a project, which was then realized with the experience of Stefan Frey and the local workers.

Eng. Ricci, project manager, accompanied us on the roof of the hotel to explain how the system is made by standing in front of the installed panels and the relative auxiliary systems.

The energy solution consists of two distinct systems: the photovoltaic system, and the solar thermal system. There is also a large skylight that allows light to enter three floors under the roof, thanks to the glazed portions of the different floors.

The FSA12 group had already seen photovoltaic systems in the previous weeks, in the rural areas of Honduras and Guatemala, so the explanation was directly targeted to applications on urban residential building.

For the PV, 100 230W PV panels have been installed, so the peak power installed is 23 kW. Given the proximity of Costa Rica with the equator, exposure to the south becomes less crucial for good production, and exposure to the West and East is also exploited. This difference in exposure, however, causes a difference in irradiation and efficiency between the various parts, which is managed with 4 6kW inverters.

A more detailed explanation was also dedicated to the solar thermal system, which we had not yet had the opportunity to study.

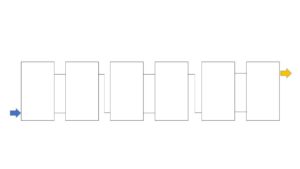

On the roof you can visit the part of the primary circuit, i.e. the flat thermal panels and we have been told that, given the environmental conditions of Costa Rica, these panels are optimal, for example to put vacuum panels would provide too high a temperature. The 30 panels installed are arranged with a first grouping of six panels in parallel for preheating, in series with four parallel strings formed by a series of three pairs of panels.

Figure 1 Arrangement of the panels in each string

This arrangement between series and parallels allows water heating to be optimized. An expansion vessel is connected to the plant, located inside the room where the lift operating machines are located.

After the Professor’s lesson on the reason for the presence and the sizing of the expansion vessels, we went to the basement of the hotel to see the secondary circuit consisting of accumulation, exchangers and gas integration.

Here the engineer Ricci showed us the various parts that complete the plant. It starts with a 3000-liter tank that is connected to the roof panels and closes the primary circuit.

There is a control unit that, through sensors and pumps, manages the whole system. If the panel sensor detects a temperature 4 degrees higher than that of the tank, the control unit activates the pump so that the water is heated.

From this tank starts a tube that passes through the high efficiency exchanger. This is a plate exchanger, of which the group has noticed efficiency and small size. On the other side of this heat exchanger there is a tank equal to the previous one, which is the first one that has been installed. The control unit, again using temperature sensors located in the tanks, activates and deactivates the exchanger pumps.

In a second moment, another 3000-liter water tank was added in succession to the first one. There is a recirculation function between the tanks so that the distribution temperature is always available to the user). When the new hotel manager arrived, he imposed that 10,000 liters of hot water had to be always available and could be regenerated in up to an hour. Two great updates have been made to accommodate this request. The first was to get a 5000-liter tank made to measure so that it could pass through the entrance to the basement, and connect it in succession to the other two, and the second was to install gas boilers connected to this last tank that start only when the water temperature falls below 50 degrees.

Only a few weeks after the installation they realized that this request was excessive and there was no need to produce such a quantity of hot water in such a short time, so now only two of the small boilers are used and the others are not.

Later, the engineer Ricci explained to us that the hotel has 10 columns of water that go up the 5 floors in order to bring water to all the rooms, and that in this way the water cools down, especially in the rooms more distant and perhaps not used for a few days. Being a hotel of excellence, in order to provide the best possible service, they have obviously installed a good hot water recirculation system. This allows hotel guests to have hot water instant after opening the faucet instead of having to wait for the water to be replaced in the whole pipe.

At the end, personally, I think it was a very good experience for the FSA12 group because it put us in touch with the most efficient technology to use solar energy in water heating, which together with photovoltaic and direct light make this much more sustainable building and a model for the city and cooperation.